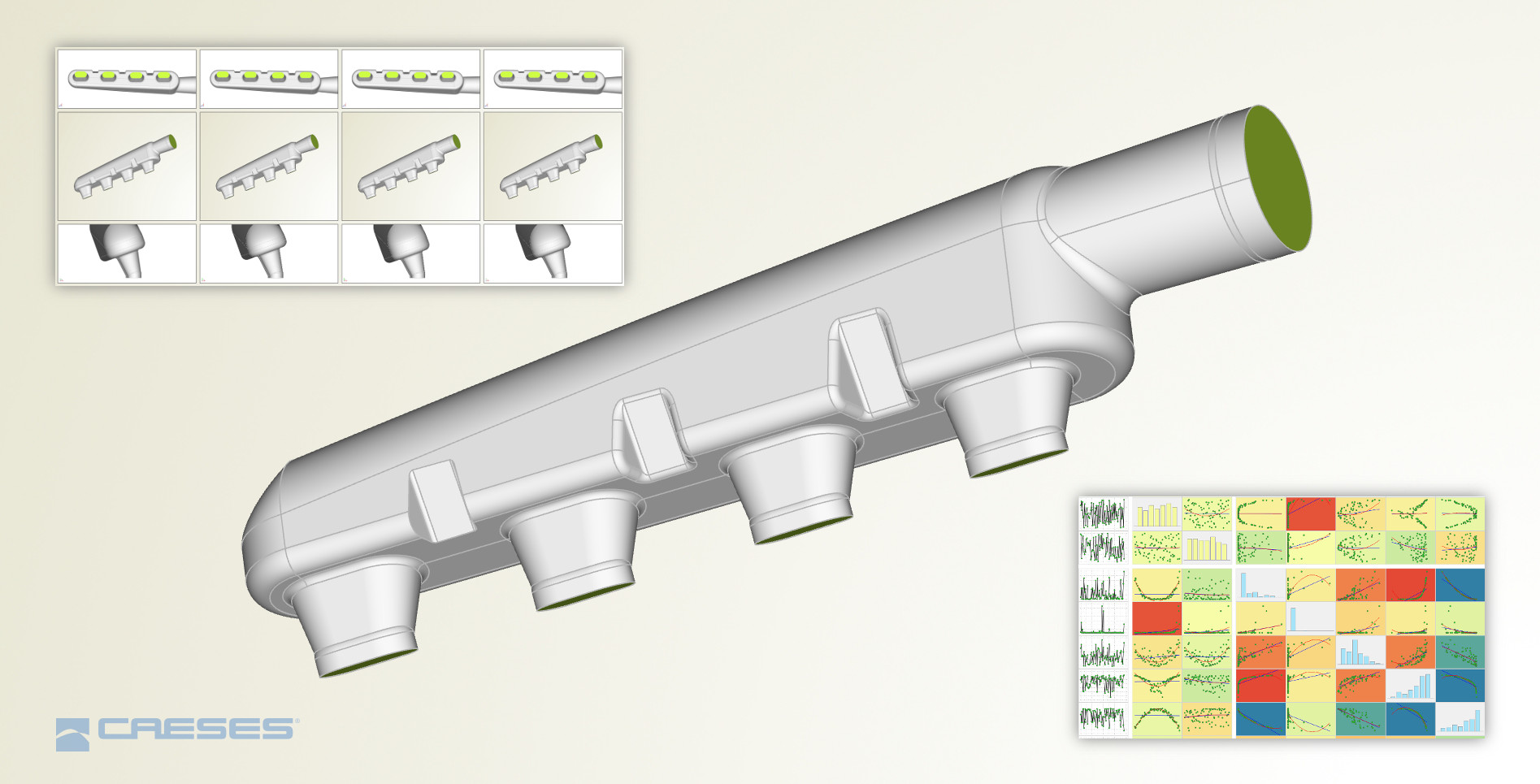

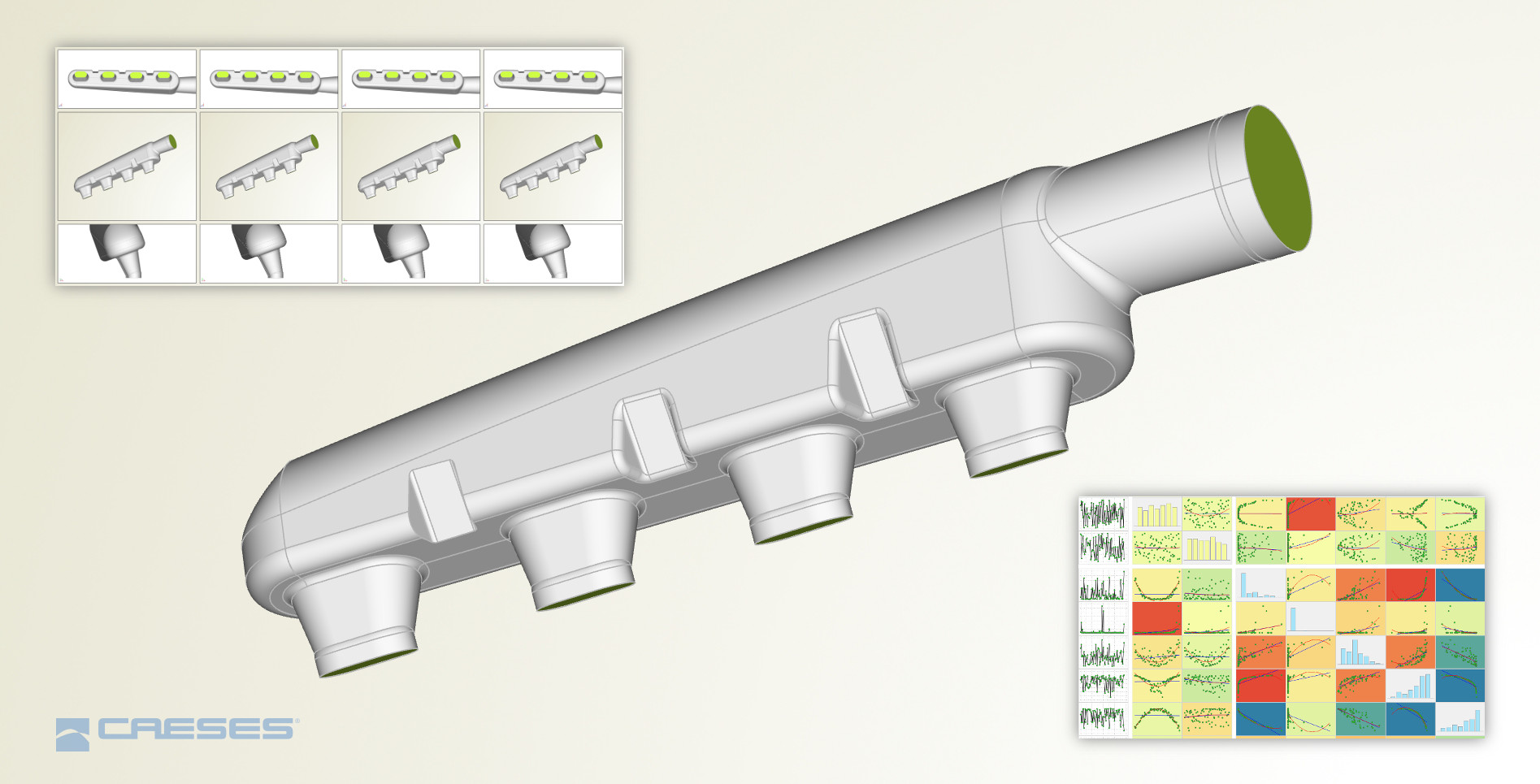

CAD FOR AUTOMATED SHAPE OPTIMIZATION

CAESES is a flexible CAD modeler for fast and robust design studies with your simulation tools. Integrated capabilities for process automation and shape optimization make it an all-in-one design system for simulation engineers.

CAESES

Optimized products make you stand out from the mass in the engineering market. CAESES® helps you to achieve this goal by letting you create powerful robust geometry models that can be integrated into any simulation-driven optimization loop. This makes CAESES® an efficient and automated CAD engine for faster design studies with your meshing and simulation tools.

CAESES® gives you flexible parametric modeling, but also integrated capabilities for process automation and shape optimization. This combination in a single user interface makes it an all-in-one design system for simulation engineers from any industry.

Why CAESES?

CAESES® stands for “CAE System Empowering Simulation” and its ultimate goal is to design optimal flow-exposed products. It focuses heavily on simulation engineers that need automation, in particular in the context of geometry generation.

CAESES® focuses on automation!

With a focus on automation, CAESES helps you to be more productive and to drive more value from your existing simulation software investments. Your product development benefits from a massive acceleration, while fostering design exploration and innovation.

Automation-Ready

As a central component of CAESES, the creation of complex geometry variants is automated and 100% robust, thanks to the dependency-based modeling approach – as opposed to the history-based approach of other CAD systems. The entire process can be optionally scripted to run in batch mode.

All generated geometries are clean and watertight without any manual pre-processing, which saves you hours of work. CAESES models contain fixed patch identifiers (surface IDs) to automate the meshing process.

Efficient Geometry

CAESES® models have less parameters which saves computational time in optimization processes. You can even build design constraints into your CAESES® models, such as cross-sectional areas, minimum distances to keep, manufacturing constraints, hard points, etc. This ensures that only valid designs are created during optimization runs. No more waste of time due to infeasible designs!

Find Optimal Designs

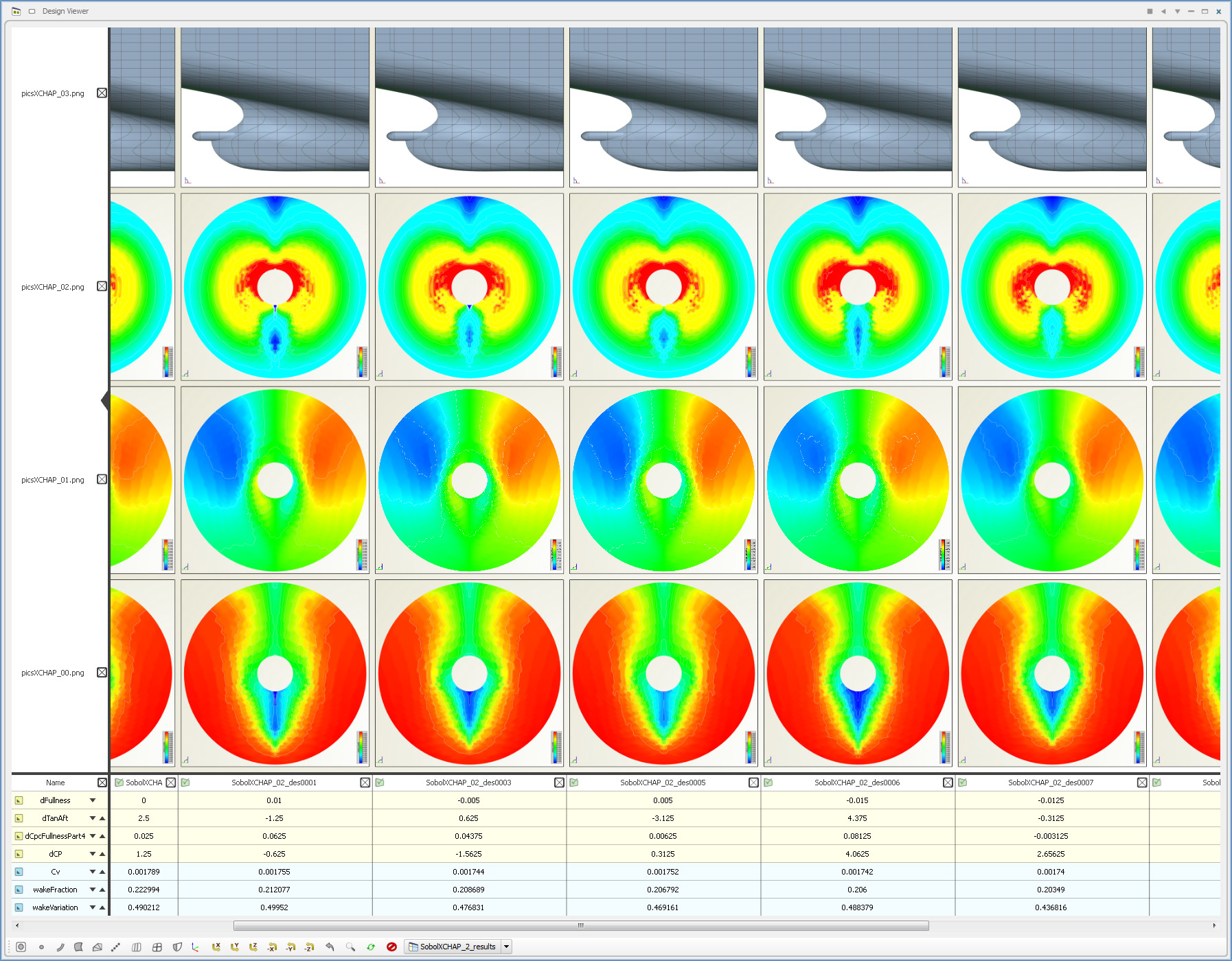

CAESES® itself contains no CFD or other simulation methods, instead it seamlessly integrates your existing tools to create a closed loop. The capabilities for automation of simulation tools let you plug in flow and structural analysis.

In addition, CAESES® comes with integrated strategies for parameter studies and shape optimization. Together with the geometry modeling, you have everything you need to investigate large sets of design candidates in a massively reduced time frame.

CAESES can also be used in combination with existing optimization tools, such as Dakota, OptiSLang, Optimus, ModeFrontier etc. In these situations, CAESES runs in the background as efficient and robust geometry engine.

Applications

CAESES® is used in various industries. Typical areas of interest include ship hulls, turbomachines, ducts and manifolds, engine components, aerodynamic bodies such as aircraft and race car components, mixers, propellers, etc. CAESES® is suited for both internal and external flow applications.

Who Uses CAESES?

More than 150 leading companies all over the world use CAESES® for the design and shape optimization of engineering products. Examples are SIEMENS, Caterpillar, MTU, Hyundai, SAMSUNG, Parrot, Grundfos, Kawasaki, just to pick a few. See the industries page for a list of selected references.